2nd Generation Transport

The maintenance of tape decks requires careful attention to their mechanical components, especially the tape transport mechanism. Working with classic Nakamichi transport mechanisms is a true fun — they represent the mastership of the pre-Sankyo era.

These mechanisms were used in models such as the 480, 481, 482, 660ZX, 670ZX, and the legendary 680ZX. Before Nakamichi’s partnership with Sankyo, this type of transport system was installed up to the LX-5 model.

Nakamichi 660ZX Model

Among these, the Nakamichi 660ZX tape deck stands out as one of the most beautiful and best-sounding cassette decks ever produced. Its analog VU meters with needles are pieces of art in themselves. While their design is heartwarming, audiophiles primarily value this model for its sound. The sonic quality of tape decks depends not only on electronics but, above all, on mechanical durability.

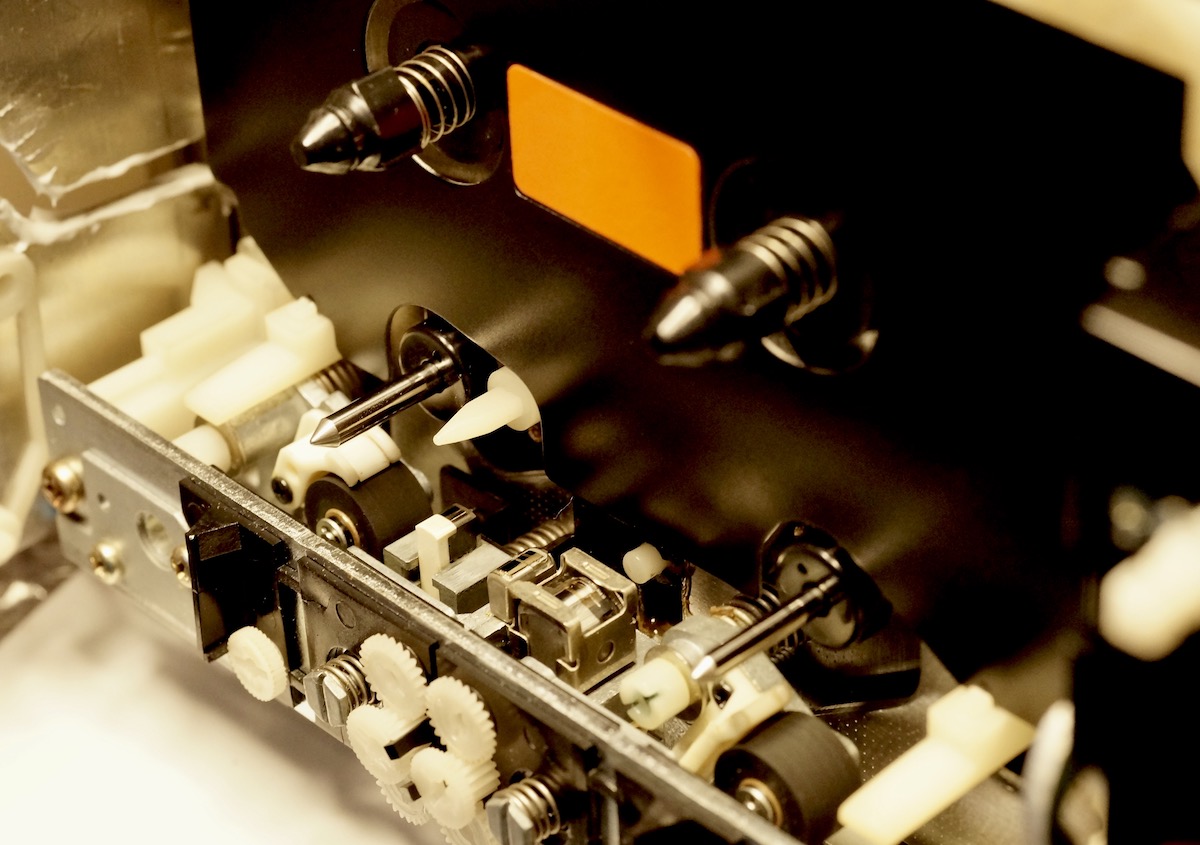

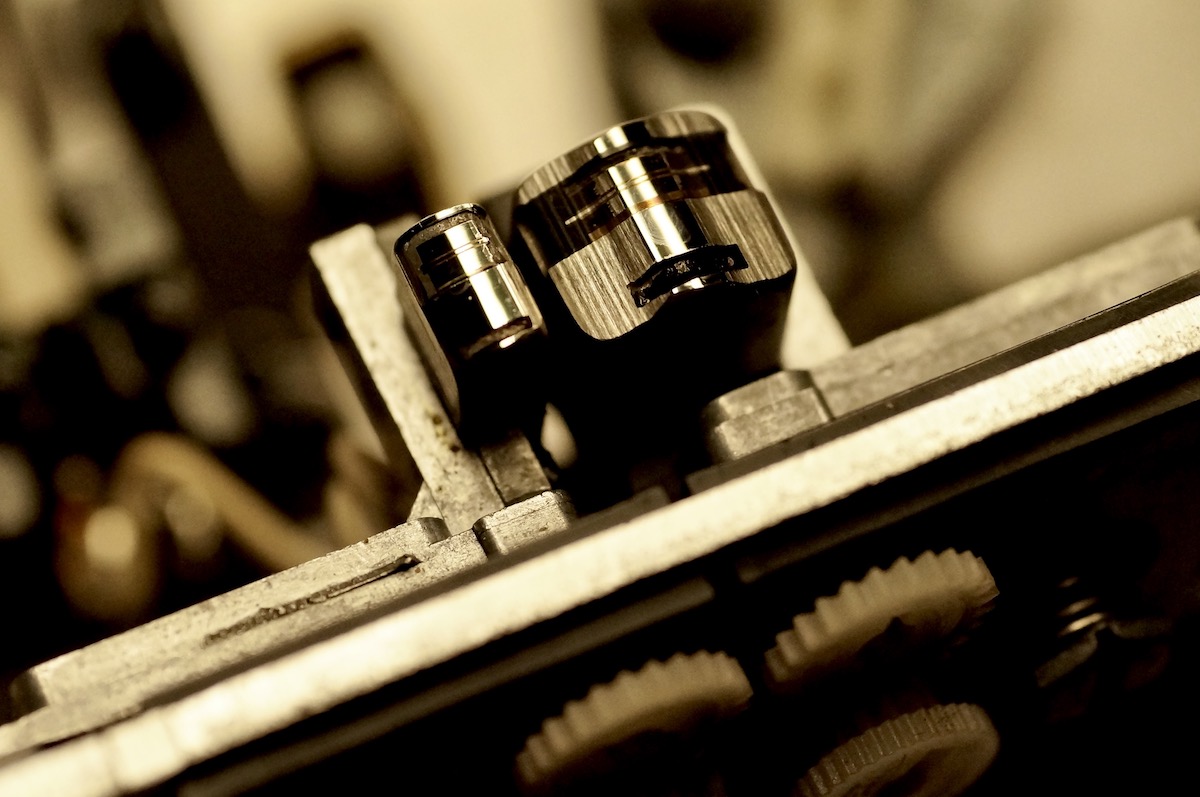

The transport mechanism in the 660ZX is the classic second-generation Nakamichi type with a closed-loop dual capstan system. The flywheels, engineered with different diameters, operate at distinct resonant frequencies, thereby minimizing overall interference.

This robust mechanism is impressively large, spanning nearly one-third of the deck’s front panel length. Despite being built from plastic components mounted on an aluminum base plate, its anti-vibration properties surpass those of competing manufacturers’ mechanisms from that era. These mechanisms have demonstrated remarkable durability and longevity, continuing to perform reliably more than four decades after production. With proper and timely maintenance, a 660ZX can easily operate for many additional years to come.

Maintenance

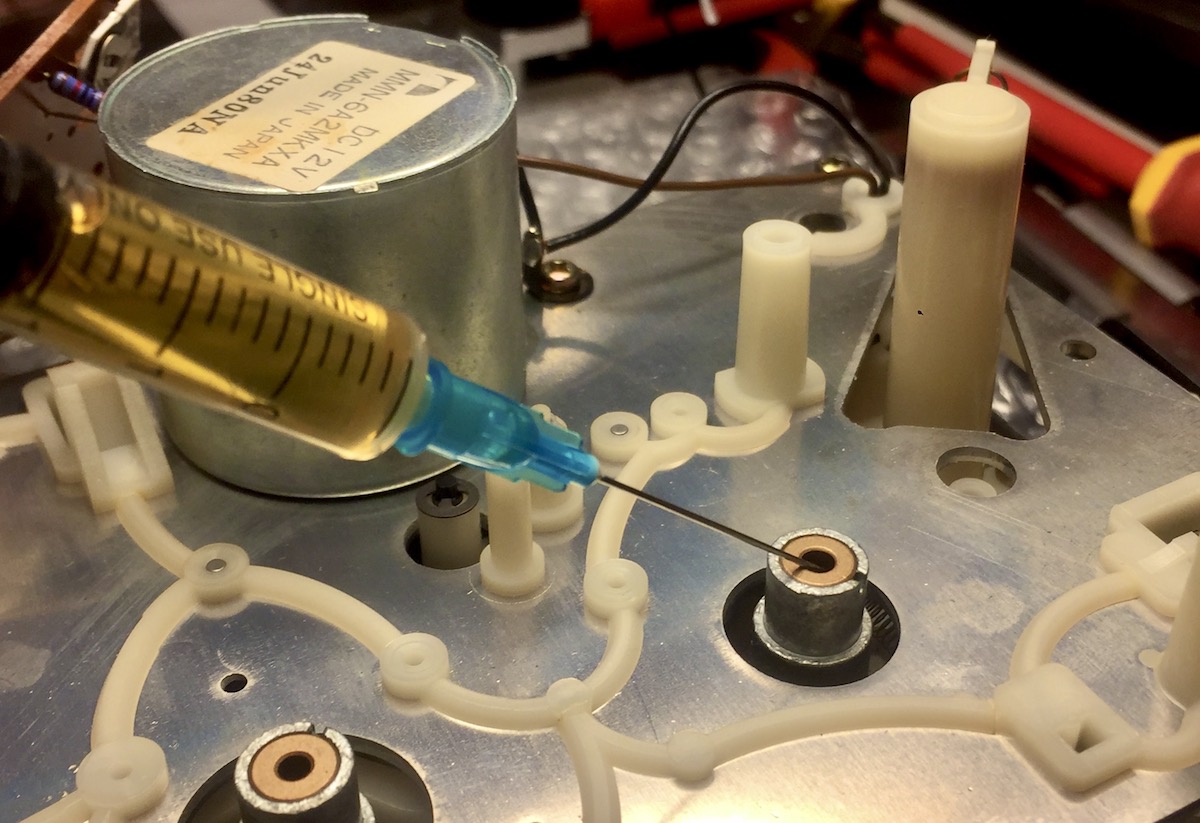

Proper transport mechanism maintenance extends beyond routine belt replacement, which is still a common but incomplete practice in many service facilities. Comprehensive maintenance requires full disassembly of the transport, degreasing and removal of dirt, and re‑lubrication of all specified parts in accordance with the service manual (SM).

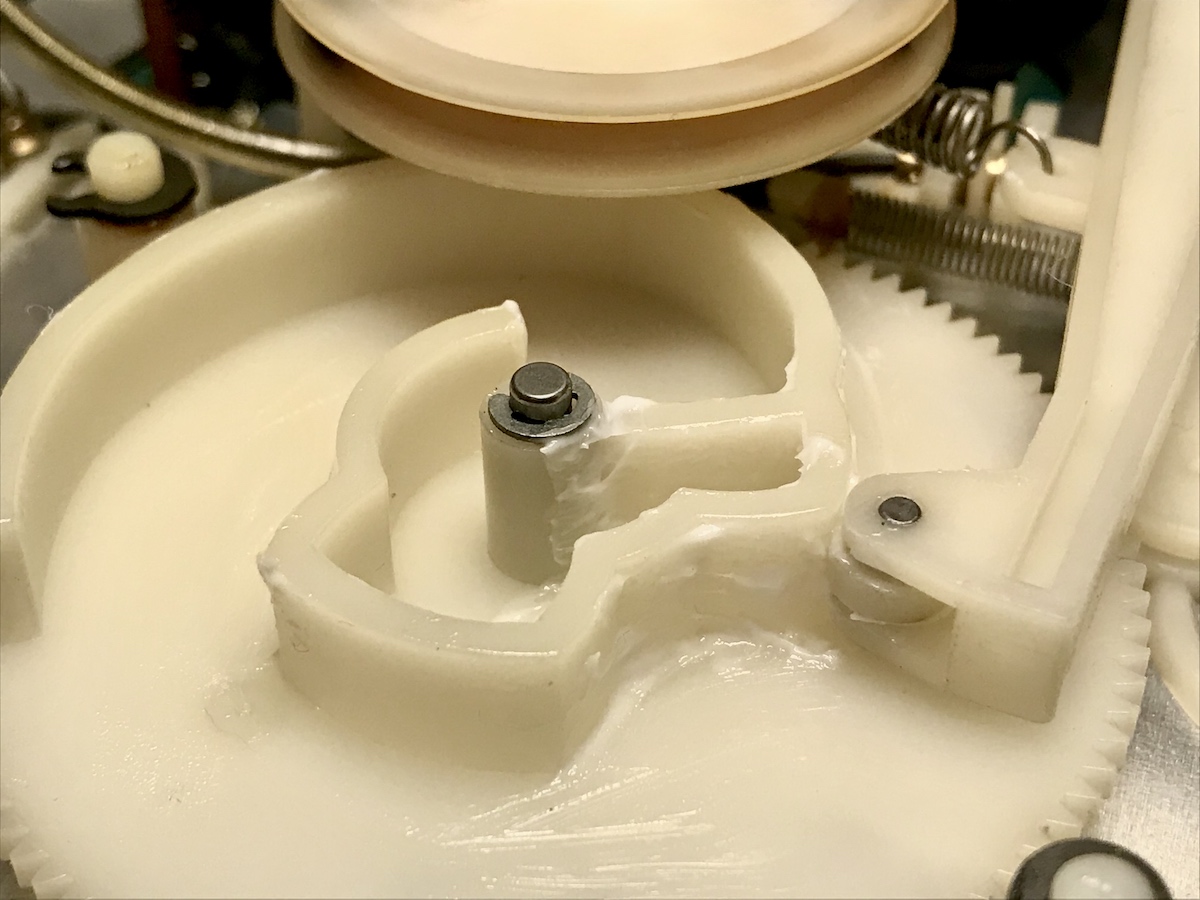

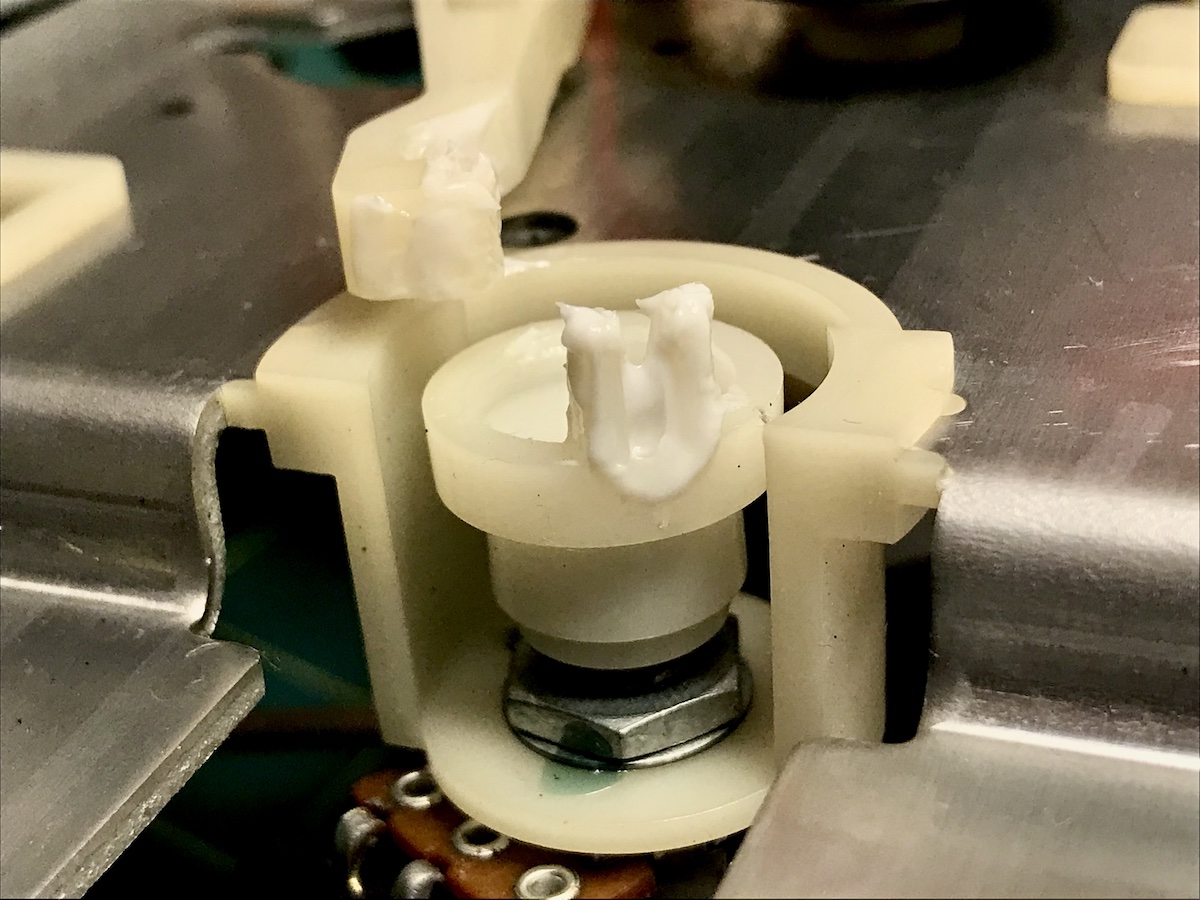

Each part requires a specific type of lubricant. For example, synthetic motor oil (SAE 0W‑20) is recommended for the flywheel shafts lubrication. Whereas lubricating of plastic parts requires a completely different type of lubricant: synthetic hydrocarbon oil-based grease, ideally EM-30L. This type of grease does not contain silicone, thereby preventing problems with contact point failures.

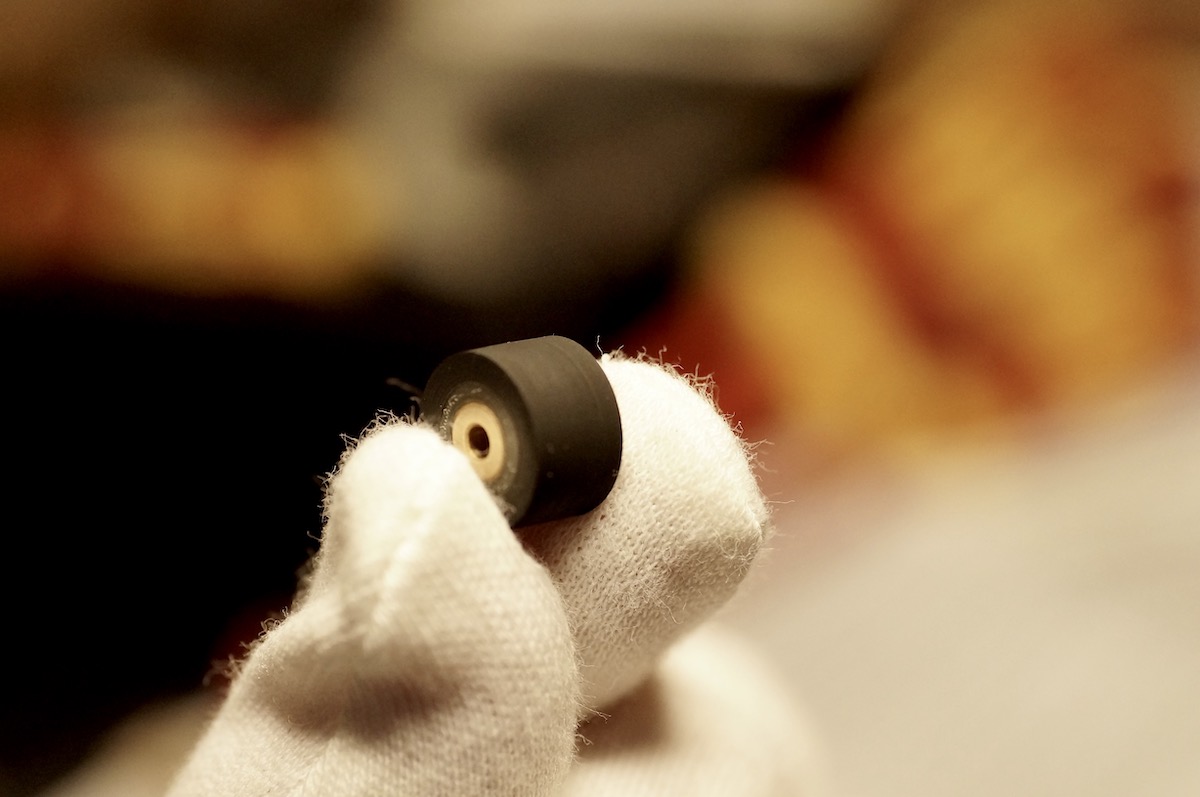

When cleaning pinch rollers, aggressive solvents should be avoided. Instead, based on our experience, it is highly recommended to use dedicated rubber cleaners and restorers to preserve the rubber’s elasticity.

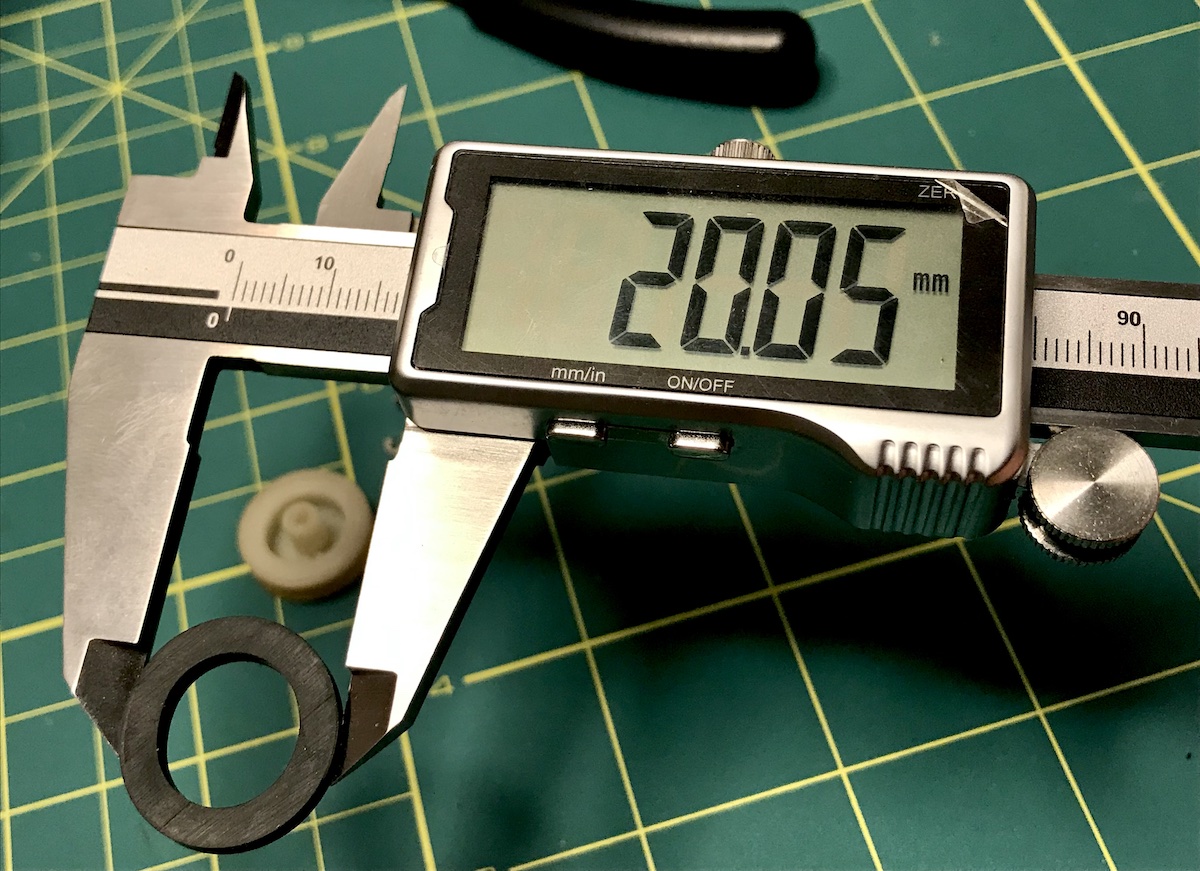

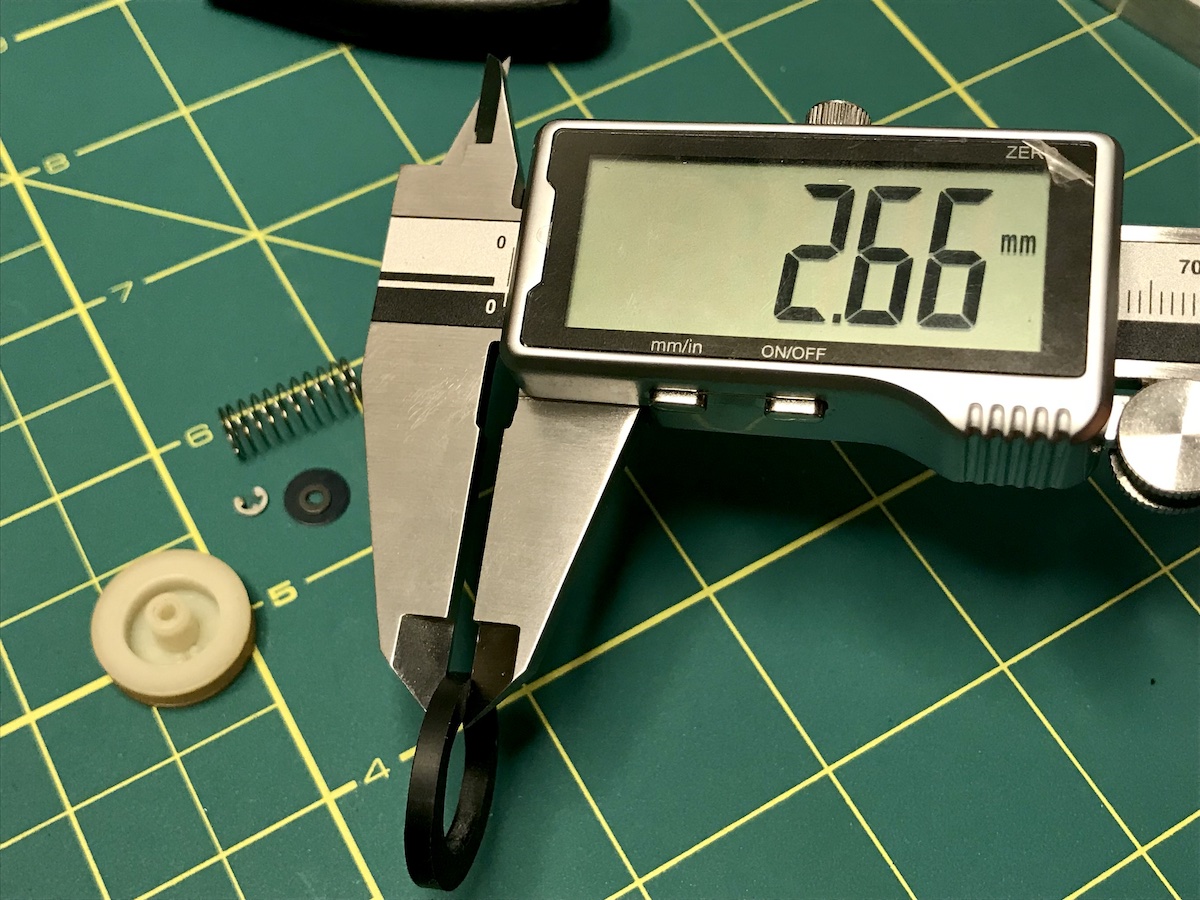

Idler Dimensions

Replacement of the idler (small rubber ring) is also frequently necessary. Accessing this part can be challenging for inexperienced technicians. It is critical to use an idler of the correct dimensions rather than inexpensive, non‑genuine parts often found from unverified eBay sellers. Reference images showing the correct idler size for Nakamichi transport mechanisms are provided.

After the mechanical cleaning and lubrication process, demagnetizing the playback head is a mandatory step. This procedure ensures optimal audio performance and completes the minimum required scope of transport maintenance.

Further materials detailing cassette deck measurement techniques and alignment procedures will be presented in a separate publication.